PROJECT MANAGEMENT

14 May 2022

Off

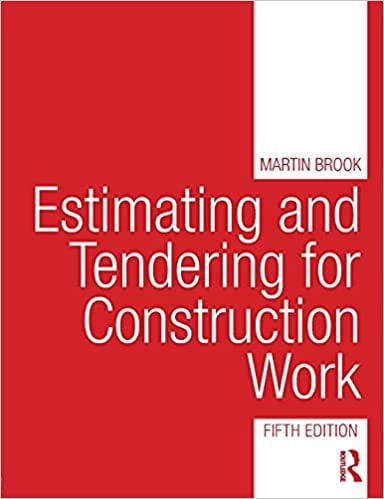

Estimating and Tendering for Construction Work Fifth Edition Free PDF

By The Engineering CommunityEstimating and Tendering for Construction Work Fifth Edition Free PDF Estimators need to understand the consequences of...

Recent Posts

Bentley Products

PROJECT MANAGEMENT

14 May 2022

Off

Estimating and Tendering for Construction Work Fifth Edition Free PDF

By The Engineering CommunityEstimating and Tendering for Construction Work Fifth Edition Free PDF Estimators need to understand the consequences of entering into a contract, often defined by complex conditions and documents, as well as to appreciate the technical requirements of...

29 January 2022

Off

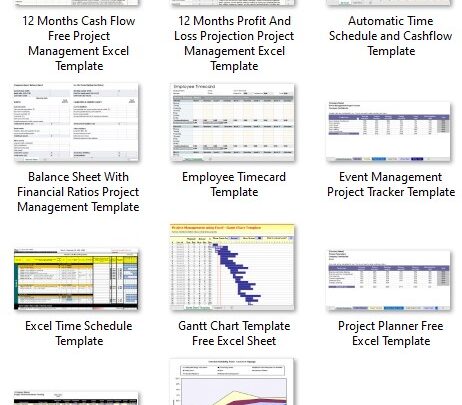

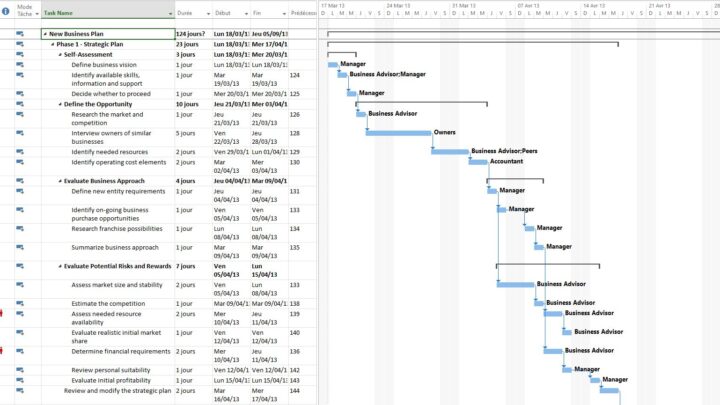

Project Management Planning and Schedule Free Spreadsheets

By The Engineering CommunityProject Management Planning and Schedule Free Spreadsheets Download free the best collection of customizable project plan templates for Microsoft...

20 November 2021

Off

Business Plan Model MS Project Free Template

By The Engineering CommunityBusiness Plan Model MS Project Free Template Download Link To download more project management resources please visit www.managementproject.net