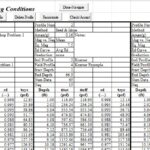

Concrete Box Culvert Design Based on AASHTO 17th & ACI 318-14 Spreadsheet

2 January 2025Table of Contents

Concrete Box Culvert Design Based on AASHTO 17th & ACI 318-14 Spreadsheet

Learn how to design concrete box culverts effectively. This guide covers key steps, tips, and best practices for creating durable and efficient drainage structures.

What is a Concrete Box Culvert?

A concrete box culvert is a reinforced concrete structure used primarily for drainage, road crossings, and stormwater management. Its rectangular or square shape makes it ideal for handling water flow while supporting heavy loads like vehicles or soil pressure. These culverts are widely used in civil engineering projects due to their strength, durability, and versatility.

Why is Proper Design Important?

Designing a concrete box culvert requires careful planning and precision. A well-designed culvert ensures:

- Effective Drainage: Prevents flooding and waterlogging.

- Structural Stability: Supports heavy loads without failure.

- Longevity: Reduces maintenance costs and extends the structure’s lifespan.

- Safety: Protects infrastructure and the surrounding environment.

Key Steps in Concrete Box Culvert Design

Here’s a step-by-step guide to designing a concrete box culvert:

- Define Project Requirements:

- Determine the culvert’s purpose, size, and location.

- Consider environmental factors like soil type, water flow, and weather conditions.

- Calculate Loads:

- Analyze dead loads (culvert weight), live loads (traffic), and environmental loads (water pressure, soil pressure).

- Material Selection:

- Choose high-quality concrete and reinforcement materials to ensure strength and durability.

- Structural Analysis:

- Perform calculations to ensure the culvert can withstand applied loads without cracking or failing.

- Reinforcement Design:

- Determine the required reinforcement to prevent cracks and ensure structural integrity.

- Check for Compliance:

- Verify that the design meets industry standards and local regulations.

Tips for Efficient Culvert Design

- Use Design Software: Tools like AutoCAD or specialized spreadsheets can streamline calculations and improve accuracy.

- Collaborate with Experts: Work with structural engineers to ensure the design is safe and compliant.

- Consider Environmental Impact: Account for factors like soil erosion, water flow, and weather conditions.

- Plan for Maintenance: Design the culvert with accessibility for future inspections and repairs.

Benefits of Concrete Box Culverts

- Durability: Reinforced concrete ensures long-term performance even in harsh conditions.

- Versatility: Suitable for a wide range of applications, from small drainage systems to large road crossings.

- Cost-Effective: Low maintenance and long lifespan reduce overall project costs.

- Eco-Friendly: Helps manage stormwater and prevent environmental damage.

Common Challenges in Culvert Design

- Load Variations: Accounting for different types of loads (e.g., traffic, soil pressure) can be complex.

- Environmental Factors: Soil type, water flow, and weather conditions must be carefully considered.

- Compliance: Ensuring the design meets local and industry standards can be time-consuming.

Get Started with Your Culvert Design

Whether you’re a civil engineer, contractor, or student, mastering concrete box culvert design is a valuable skill. By following best practices and using the right tools, you can create efficient, durable, and safe culverts for any project.