Bridge Bearings – POT BEARINGS

12 June 2019Table of Contents

Bridge Bearings – POT BEARINGS

What are Bearings ?

Bearings are mechanical systems which transmit loads from the superstructure to the substructure. In a way, bearings can be thought of as the interface between the superstructure and the substructure.

Their principal functions are as follows:

1.To transmit loads from the superstructure to the substructure, and

2.To accommodate relative movements between the superstructure and

the substructure.

Types of Bearings:

Bearings may be classified in two categories:

1.Fixed bearings (allow rotations only)

2.Expansion bearings (allow both rotational and translational movements)

Following are the principal types of bearings currently in use:

1.Sliding Bearings

2.Rocker and Pin Bearings

3.Roller Bearings

4.Elastomeric Bearings

5.Curved Bearings

6.Pot Bearings

7.Disk Bearings

Pot Bearings

A pot bearing comprises a plain elastomeric disk that is confined in a shallow steel ring, or pot. Vertical loads are transmitted through a steel piston that fits closely to the steel ring (pot wall).

Translational movements are restrained in a pure pot bearing, and the gravity loads are transmitted through the steel piston moving against the pot wall. To accommodate translational movement, a PTFE sliding surface must be used. Keeper plates are often used to keep the superstructure moving in one direction.

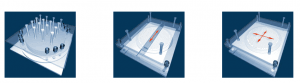

Types of Pot Bearings

In general, the movement accommodated by fixed and expansion bearings can be classified by the following:

- Fixed bearings allow for rotation only

- Guided expansion bearings allow for rotation and longitudinal translation only

- Multi-directional expansion bearings (sliding bearings) allow for rotation and translation in any direction

Figure 1 : Types of Por Bearings

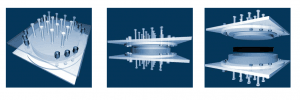

Fixed Pot-Bearings

A non-reinforced elastomer is placed between a precisely milled steel pot and a cylindrical lid.

Vertical loads are transmitted through a steel piston that fits closely to the steel pot wall. Flat sealing rings are used to contain the elastomer inside the pot. The elastomer behaves like a viscous fluid within the pot as the bearing rotates. Because the elastomeric pad is confined, much larger load can be carried this way than through conventional elastomeric pads.

Figure 2 : Fixed Pot-Bearings

Guided Pot-Bearings

A Uniaxial Displaceable Pot Bearing (Guided Pot Bearing) releases the lateral movements of bridge in any one direction utilizing a guide on the lid and a guiding groove in the gliding plate.

The gliding ability is accomplished by the embedded PTFE (Teflon®) disc and the gliding austenitic steel, which is welded onto the bottom of the gliding plate.

Figure 3 : Guided Pot-Bearings

Sliding Pot-Bearings

The Multiaxial Displaceable Pot Bearing (Sliding Pot Bearings) releases lateral movements of the bridge in all directions.

The gliding ability is accomplished by the embedded PTFE (Teflon®) disc and the gliding austenitic steel, which is welded onto the bottom of the gliding plate.

Figure 4 : Slidin Pot-Bearings

Components of Pot-Bearing

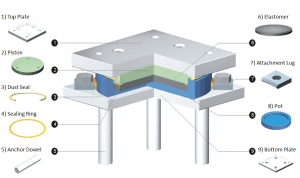

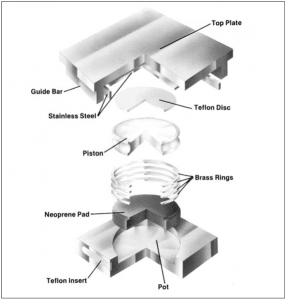

Figure 5 : Components of Pot-Bearing (Fixed Pot-Bearing)

Figure 6 : Components of Pot-Bearing (Guided Pot-Bearing)

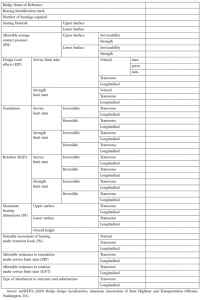

Bearing Schedule

First, the vertical and horizontal loads, the rotational and translational movements from all sources including dead and live loads, wind loads, earthquake loads, creep and shrinkage, prestress, thermal and construction tolerances need to be calculated. Then, the table below may be used to tabulate these requirements.

Table 1 : Bearing Schedule Requirements

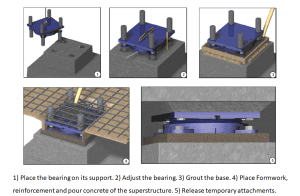

Installation of Pot-Bearing

Figure 7 : Steps to install Pot-Bearings

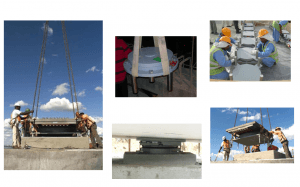

Figure 8 :Installation oof Pot-Bearings