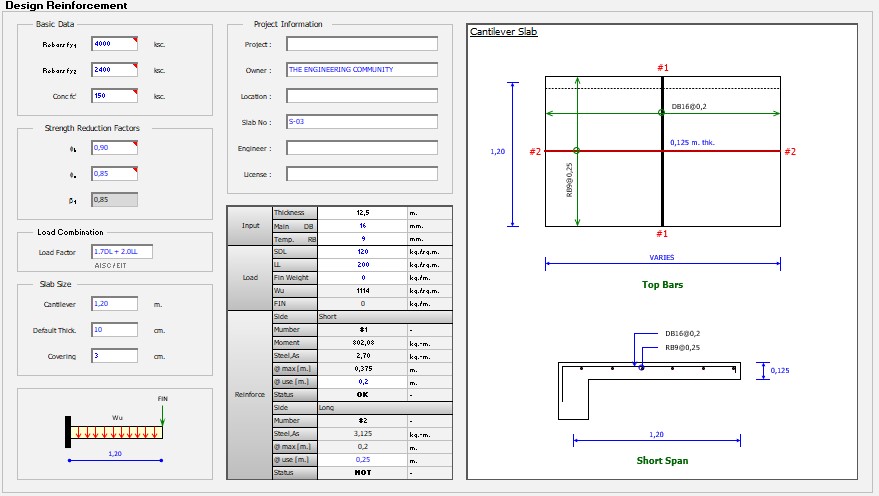

Cantilever Slab Design Reinforcement Spreadsheet

24 February 2025Table of Contents

Cantilever Slab Design Reinforcement Spreadsheet

A cantilever slab is a reinforced concrete slab that extends beyond its supporting beam or column without any external bracing. This overhanging portion is free on one end while fixed at the other, creating a visually striking architectural feature. Cantilever slabs are commonly used in balconies, canopies, and even bridge decks, offering an elegant, floating appearance.

How Do Cantilever Slabs Work?

Cantilever slabs function by transferring the load back to the fixed support, where the bending moment is highest. The upper portion of the slab experiences compression, while the lower part undergoes tension. To resist these forces, steel reinforcement bars are strategically placed at the top of the slab.

Applications of Cantilever Slabs

Cantilever slabs are versatile and are used in various applications, including:

- Balconies and Terraces: Offering an extended outdoor space without requiring external columns.

- Canopies and Awnings: Providing shade and protection from the elements.

- Bridge Decks: Enhancing the aesthetic appeal of bridges while maximizing the span.

- Building Overhangs: Creating dramatic architectural statements with a floating appearance.

Design Considerations for Cantilever Slabs

Designing a cantilever slab involves several critical considerations:

1. Length of the Cantilever

The length of the cantilever should typically not exceed one-third of the supported span to ensure stability and prevent excessive deflection.

2. Load-Bearing Capacity

Proper analysis of dead loads (self-weight) and live loads (e.g., people, furniture, wind) is essential for a safe design.

3. Reinforcement Details

Steel reinforcement bars should be provided at the top portion of the cantilever to resist tension. Additional negative reinforcement is required at the fixed end.

4. Deflection Control

To avoid sagging, deflection limits must be checked as per standard building codes like ACI, IS, or Eurocode.

5. Material Selection

High-strength concrete and corrosion-resistant steel are recommended for durability and safety.

Advantages of Cantilever Slabs

Cantilever slabs offer numerous advantages, such as:

- Aesthetic Appeal: Creating a modern and sleek architectural look.

- Space Optimization: Maximizing usable space without obstructive columns.

- Versatility: Suitable for residential, commercial, and industrial applications.

- Structural Stability: Efficient load transfer to the fixed support.

Disadvantages of Cantilever Slabs

Despite their benefits, cantilever slabs have some limitations:

- Complex Design and Analysis: Requires careful structural calculations.

- Higher Cost: More reinforcement and high-strength concrete increase costs.

- Deflection and Cracking: Improper design can lead to excessive deflection and cracking.

- Difficulty in Construction: Precision is required during formwork and reinforcement placement.

Construction Method of Cantilever Slabs

Constructing a cantilever slab involves the following steps:

- Formwork Installation: Secure and stable formwork is essential to support the slab until it gains adequate strength.

- Reinforcement Placement: Place reinforcement bars as per design specifications, ensuring adequate anchorage and lap length.

- Concrete Pouring and Curing: Pour high-strength concrete and ensure proper compaction to avoid voids. Curing is essential for achieving desired strength.

- Removal of Formwork: Formwork should only be removed after the concrete has gained sufficient strength to support the load.

Common Mistakes to Avoid

- Insufficient Reinforcement: Can lead to cracking and structural failure.

- Ignoring Deflection Checks: Results in sagging and serviceability issues.

- Poor Quality Concrete: Compromises durability and strength.

- Incorrect Formwork Alignment: Causes uneven surfaces and alignment problems.

Cantilever Slab Design Example

Consider a balcony with a cantilever length of 2 meters and a width of 4 meters, subjected to a live load of 3 kN/m². Using M25 grade concrete and Fe500 steel:

- Bending Moment Calculation: M=w×l2/2=3×22/2=6kNm

- Reinforcement Requirement: Calculate the required steel area using moment and stress equations as per standard codes.

- Deflection Check: Ensure that deflection does not exceed permissible limits.

Tips for Successful Cantilever Slab Design and Construction

- Engage Experienced Structural Engineers: Accurate design calculations are crucial for safety.

- Use High-Quality Materials: Opt for durable concrete and reinforcement.

- Regular Inspections: Monitor construction phases to ensure design adherence.

- Consider Environmental Factors: Account for wind loads, seismic activity, and other environmental influences.

Conclusion

Cantilever slabs are an architectural marvel that offers aesthetic beauty, functional space utilization, and structural efficiency. Despite the complex design and construction requirements, the advantages outweigh the challenges when executed properly. By adhering to standard codes, using high-quality materials, and employing skilled professionals, cantilever slabs can be a striking and reliable feature of modern buildings.