Cement Manufacturing Process

28 August 2018Table of Contents

Cement Manufacturing Process

Cement is the basic ingredient of construction and the most widely used construction material. It is a very critical ingredient, because only cement has the ability of enhancing viscosity of concrete which in returns provides the better locking of sand and gravels together in a concrete mix.

CEMENT MANUFACTURING PROCESS PHASES

Production of cement completes after passing of raw materials from the following six phases. These are;

- Raw material extraction/ Quarry

- Grinding, Proportioning and Blending

- Pre-heater Phase

- Kiln Phase

- Cooling and Final Grinding

- Packing & Shipping

CEMENT MANUFACTURING PROCESS PHASE 1: RAW MATERIAL EXTRACTION

Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand & clay fulfill the need of silicon, iron and aluminum.

Extraction of raw material and crushing of material

Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant.

There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

Before transportation of raw materials to the cement plant, large size rocks are crushed into smaller size rocks with the help of crusher at quarry. Crusher reduces the size of large rocks to the size of gravels.

CEMENT MANUFACTURING PROCESS PHASE II: PROPORTIONING, BLENDING & GRINDING

The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay.

Proportioning of raw material at cement plant laboratory

Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table. Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller. Roller crushes the material to a fine powder and finishes the job. Raw mix is stored in a pre-homogenization pile after grinding raw mix to fine powder.

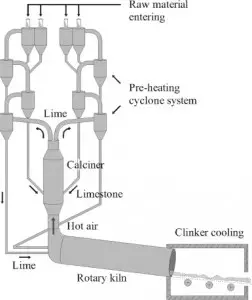

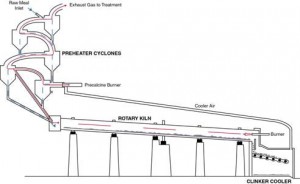

CEMENT MANUFACTURING PROCESS PHASE III: PRE-HEATING RAW MATERIAL

After final grinding, the material is ready to face the pre-heating chamber. Pre-heater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln. Pre-heating chamber utilizes the emitting hot gases from kiln. Pre-heating of the material saves the energy and make plant environmental friendly.

Preheating of raw material | Vertical cyclone

CEMENT MANUFACTURING PROCESS PHASE IV: KILN PHASE

Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide. High temperature of kiln makes slurry of the material.

Rotary kiln

The series of chemical reactions between calcium and silicon dioxide compounds form the primary constituents of cement i.e., calcium silicate. Kiln is heating up from the exit side by the use of natural gas and coal. When material reaches the lower part of the kiln, it forms the shape of clinker.

CEMENT MANUFACTURING PROCESS PHASE V: COOLING AND FINAL GRINDING

After passing out from the kiln, clinkers are cooled by mean of forced air. Clinker released the absorb heat and cool down to lower temperature. Released heat by clinker is reused by recirculating it back to the kiln. This too saves energy.

Clinker cooling | Cement making process

Final process of 5th phase is the final grinding. There is a horizontal filled with steel balls. Clinker reach in this rotating drum after cooling. Here, steel balls tumble and crush the clinker into a very fine powder. This fine powder is considered as cement. During grinding gypsum is also added to the mix in small percentage that controls the setting of cement.

Rotating ball mill

CEMENT MANUFACTURING PROCESS PHASE VI: PACKING AND SHIPPING

Transportation of cement from silos

Material is directly conveyed to the silos (silos are the large storage tanks of cement) from the grinding mills. Further, it is packed to about 20-40 kg bags. Only a small percent of cement is packed in the bags only for those customers whom need is very small. The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships.

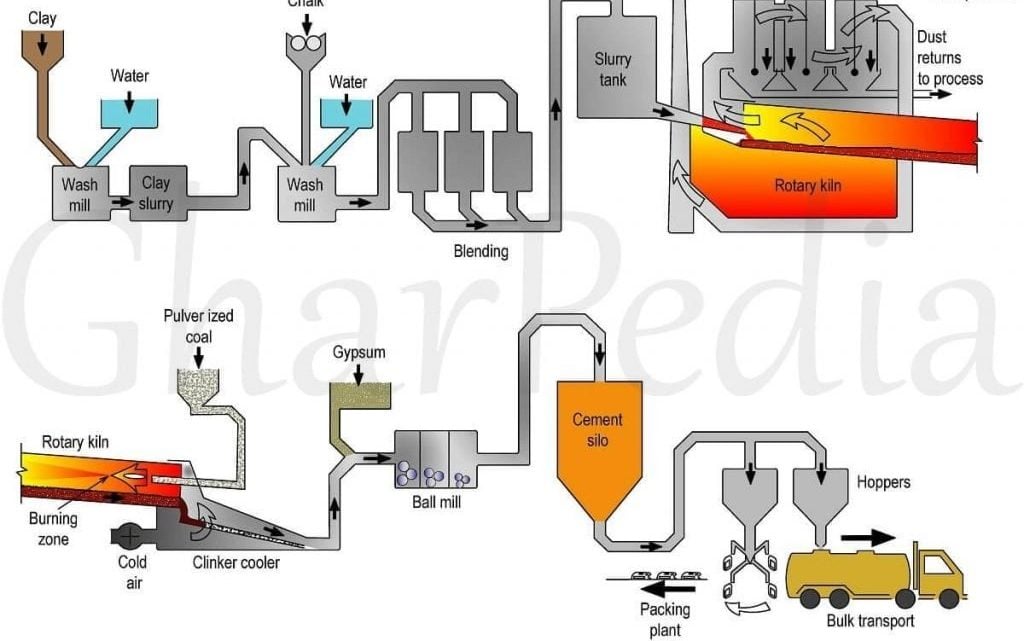

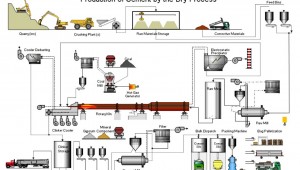

CEMENT MANUFACTURING PROCESS FLOW CHART

After explaining the complete process of cement making, flow chart would be like that. flow chart present the summary of whole process as shown below.

Cement making process flow chart