Concrete Tunnel Design and Calculation Spreadsheet Based on AASHTO and ACI

2 January 2025Concrete Tunnel Design and Calculation Spreadsheet Based on AASHTO and ACI

Concrete tunnels are marvels of engineering, serving as lifelines for transportation, water distribution, and energy systems worldwide. Designing these structures requires a perfect balance of strength, durability, and innovation. In this article, we’ll delve into the principles of concrete tunnel design, its applications, and why it’s a critical element in modern infrastructure.

What is Concrete Tunnel Design?

Concrete tunnel design refers to the planning, analysis, and construction of tunnels using reinforced or prestressed concrete. These tunnels are engineered to withstand significant loads, including soil pressure, water infiltration, and dynamic forces such as traffic or seismic activity.

Applications of Concrete Tunnels

Concrete tunnels are indispensable in:

- Transportation Infrastructure

- Subways, highways, and railways rely on tunnels to navigate challenging terrain and reduce congestion.

- Water Management Systems

- Aqueducts and drainage tunnels facilitate the distribution of water and prevention of flooding.

- Energy Projects

- Hydroelectric plants and utility tunnels house essential cables and pipelines.

- Underground Storage

- Facilities for storing hazardous materials or resources like oil and gas.

Key Principles of Concrete Tunnel Design

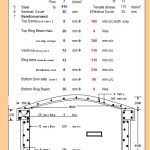

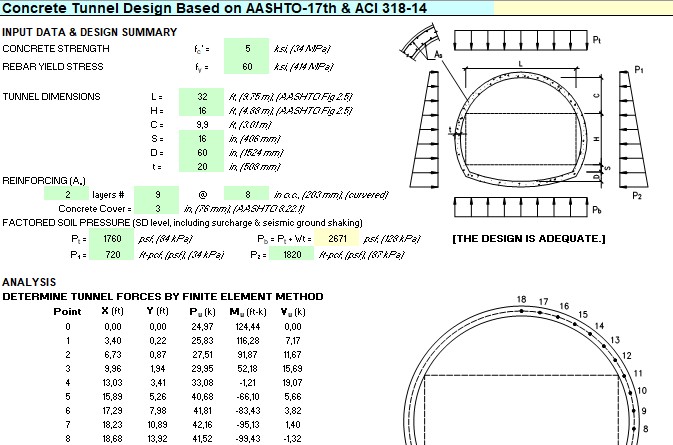

- Load Analysis

Engineers assess external forces like soil pressure, groundwater, and live loads to ensure structural integrity. - Material Selection

- Reinforced concrete is commonly used for its strength and resistance to cracking.

- Prestressed concrete may be employed in high-stress environments.

- Structural Geometry

- The shape of the tunnel (circular, horseshoe, or rectangular) depends on its purpose and geological conditions.

- Waterproofing and Drainage

- A robust waterproofing system, such as liners or membranes, prevents water infiltration.

- Drainage systems manage groundwater and prevent accumulation.

- Ventilation and Safety

- Proper ventilation ensures air quality, especially in transportation tunnels.

- Emergency exits and fire-resistant materials are incorporated for safety.

Advantages of Concrete Tunnels

- Durability

Concrete tunnels have a long lifespan, withstanding harsh environmental conditions. - Load-Bearing Capacity

They can handle heavy loads, making them ideal for urban and industrial applications. - Cost-Effectiveness

Concrete offers a balance of affordability and performance, making it a preferred material for tunnel construction. - Customizability

Concrete can be molded into various shapes and sizes to meet project-specific requirements.

Modern Innovations in Concrete Tunnel Design

- Tunnel Boring Machines (TBMs):

These machines streamline excavation and lining processes, reducing construction time and costs. - Fiber-Reinforced Concrete:

Adding fibers to concrete enhances its tensile strength and crack resistance. - Smart Monitoring Systems:

Sensors embedded in concrete track stress, temperature, and moisture levels for maintenance and safety. - Sustainable Practices:

Incorporating recycled aggregates and low-carbon cement reduces the environmental impact of tunnel construction.

Challenges in Concrete Tunnel Design

- Geological Uncertainty:

Unpredictable soil and rock conditions can complicate design and construction. - Groundwater Management:

Preventing water ingress is critical to maintaining tunnel integrity. - Seismic Considerations:

Tunnels in earthquake-prone areas require specialized design to absorb and dissipate seismic forces.

Conclusion

Concrete tunnel design is a cornerstone of modern engineering, enabling the construction of robust and efficient underground structures. From transportation to water management, these tunnels are essential for sustainable infrastructure development. By leveraging advanced materials, cutting-edge technology, and rigorous design principles, engineers can ensure these tunnels stand the test of time.