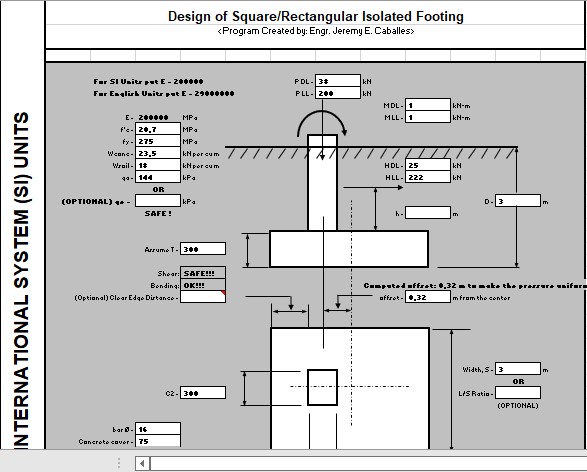

Design Of Square Rectangular Isolated Footing Spreadsheet

26 January 2022Table of Contents

Design Of Square Rectangular Isolated Footing Spreadsheet

In the world of construction, foundations play a critical role in ensuring the stability and longevity of structures. Among the various types of foundations, isolated footing stands out as one of the most widely used techniques. This article delves into the details of isolated footing, its applications, advantages, and essential considerations for its design and implementation.

What is Isolated Footing?

Isolated footing, also known as pad footing, is a type of shallow foundation used to support individual columns. It transfers the load from a single column to the soil beneath it, distributing the weight evenly to prevent excessive settlement or structural instability. Typically, isolated footings are rectangular, square, or circular in shape, depending on the load and structural requirements.

Applications of Isolated Footing

Isolated footing is commonly employed in:

- Residential and Commercial Buildings: For structures with a relatively uniform load distribution, isolated footings are ideal for supporting individual columns.

- Industrial Facilities: Used to support heavy machinery and equipment with concentrated loads.

- Bridges and Overpasses: Isolated footings are often employed for piers in these structures.

- Pavilions and Small Structures: Ideal for lightweight constructions where the loads are not excessively high.

Types of Isolated Footing

- Flat Footing: A simple rectangular or square footing designed for uniform load distribution.

- Sloped Footing: Provides better load transfer by reducing the thickness of the footing edges, saving material costs.

- Stepped Footing: Used in areas where the soil has varying bearing capacities. This type of footing increases depth in a stepwise manner.

- Circular Footing: Typically used for circular columns to achieve symmetry in load distribution.

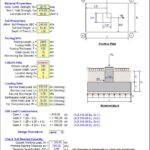

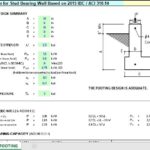

Design Considerations for Isolated Footing

- Load Calculation: Accurately determining the load from the column, including dead loads, live loads, and any other imposed loads, is crucial.

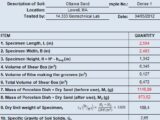

- Soil Bearing Capacity: The footing design must align with the soil’s ability to bear loads without significant settlement.

- Footing Size: The area of the footing should be sufficient to distribute the load within the soil’s safe bearing capacity.

- Reinforcement Design: Reinforcement bars are necessary to handle tensile stresses and prevent cracking.

- Depth of Footing: The depth should ensure stability against soil movement, frost action, or other environmental factors.

- Safety Margins: Always incorporate factors of safety to account for unexpected load increases or soil inconsistencies.

Advantages of Isolated Footing

- Cost-Effective: Requires less material compared to other foundation types, making it an economical choice.

- Ease of Construction: Simple design and straightforward construction process reduce time and labor.

- Flexibility: Can be tailored to various shapes and sizes to suit specific structural requirements.

- Durability: Properly designed and constructed isolated footings ensure long-term stability and performance.

- Localized Support: Ideal for structures with isolated load points.

Limitations of Isolated Footing

- Not Suitable for Weak Soils: In areas with low soil bearing capacity, isolated footings may not provide adequate support.

- Limited for Heavy Structures: For massive constructions with extensive loads, other foundation types like raft or pile foundations are more appropriate.

- Settlement Risks: Uneven settlement can occur if the soil properties vary significantly beneath the footing.

Construction Process of Isolated Footing

- Excavation: Mark and excavate the area to the required depth based on the footing design.

- Soil Compaction: Compact the soil to provide a stable base for the footing.

- Base Preparation: Lay a layer of lean concrete or gravel to create a level surface.

- Reinforcement Placement: Install reinforcement bars as per the design specifications.

- Concrete Pouring: Pour the concrete mix and ensure proper compaction to eliminate air pockets.

- Curing: Allow the concrete to cure for the specified duration to achieve the desired strength.

Conclusion

Isolated footing is a cornerstone of modern construction, providing an efficient and cost-effective solution for supporting individual columns. Its versatility and ease of construction make it a popular choice across various applications. However, ensuring proper design and adherence to best practices is critical to maximizing its benefits and ensuring structural safety.