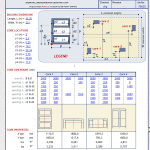

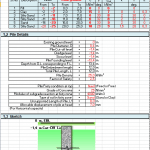

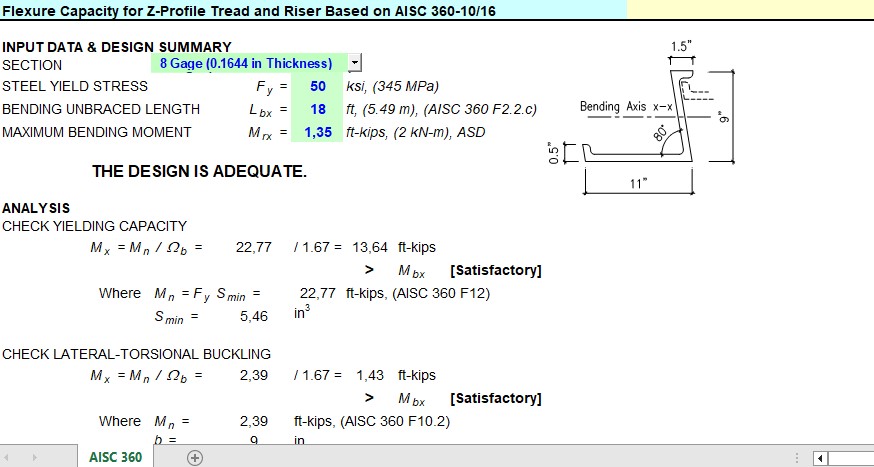

Flexure Capacity for Z-Profile Tread and Riser Based on AISC Spreadsheet

12 February 2023Flexure Capacity for Z-Profile Tread and Riser Based on AISC Spreadsheet

In the world of construction, selecting the right materials and structural elements is crucial for the success and longevity of a project. Among these essential elements, the Z-profile stands out as a versatile and efficient choice. This unique steel shape, named for its resemblance to the letter “Z,” plays a significant role in various construction applications, offering strength, flexibility, and cost-effectiveness.

In this article, we’ll dive into what the Z-profile is, its key benefits, and its common uses in the construction industry.

What is a Z-Profile?

A Z-profile, also known as a Z-section, is a steel member shaped like the letter “Z” when viewed in cross-section. It consists of two flanges connected by a web, with one flange offset vertically relative to the other. This design creates a lightweight yet strong member that can support loads effectively in various orientations.

Z-profiles are typically manufactured using galvanized steel, stainless steel, or aluminum, making them resistant to corrosion and suitable for both indoor and outdoor applications.

Key Benefits of Using Z-Profiles in Construction

- High Strength-to-Weight Ratio

- The Z-profile offers exceptional strength while remaining lightweight, reducing the overall structural load without compromising stability.

- Versatility in Applications

- Its unique shape makes it suitable for a wide range of applications, from roofing and cladding systems to structural framing.

- Ease of Fabrication and Installation

- Z-profiles are easy to cut, weld, and assemble, streamlining the construction process and reducing labor costs.

- Cost-Effectiveness

- The efficient use of materials during manufacturing ensures that Z-profiles are an economical choice for many projects.

- Corrosion Resistance

- When made from galvanized or stainless steel, Z-profiles provide long-lasting performance, even in harsh environments.

Common Applications of Z-Profiles

- Roof Purlins and Wall Girts

- Z-profiles are widely used as purlins and girts in roofing and cladding systems. They provide the necessary support for roof sheets and wall panels while reducing weight.

- Steel Frames

- In steel-framed buildings, Z-profiles serve as secondary structural members, offering additional support and stability.

- Bracing Systems

- The Z-profile’s shape and strength make it ideal for use in bracing systems, helping structures resist lateral forces such as wind or seismic loads.

- Fencing and Guardrails

- Lightweight yet durable, Z-profiles are often used in fencing and guardrail systems for both commercial and industrial applications.

- Industrial Shelving and Storage Systems

- The Z-profile’s strength and flexibility make it a popular choice for heavy-duty shelving and storage solutions.

Design Considerations for Z-Profiles

When incorporating Z-profiles into a project, engineers must consider:

- Material Selection: The choice of steel grade or aluminum alloy impacts performance and durability.

- Load Requirements: Understanding the load paths and forces acting on the Z-profile ensures optimal design.

- Coating Options: Protective coatings, such as galvanization, enhance corrosion resistance and extend the life of the profile.

- Compatibility: Z-profiles should integrate seamlessly with other structural components, ensuring a cohesive design.

Z-Profile vs. C-Profile: What’s the Difference?

While both Z-profiles and C-profiles are popular in construction, their shapes and uses differ:

- Z-Profile: Offers better overlapping capabilities, making it ideal for continuous spans in roofing and cladding systems.

- C-Profile: Commonly used for individual framing members, particularly in wall studs and door frames.

Sustainability and Z-Profiles

Z-profiles contribute to sustainable construction practices by reducing material waste during manufacturing. Additionally, they are often recyclable, aligning with green building initiatives and environmental goals.

Conclusion

The Z-profile is an indispensable component in modern construction, offering strength, versatility, and cost-efficiency. From roofing systems to structural bracing, this innovative profile adapts to a variety of applications, making it a go-to choice for engineers and builders worldwide.

Whether you’re designing an industrial warehouse, a residential project, or a commercial building, incorporating Z-profiles can enhance structural integrity and streamline construction.