Light-weight Composite Beam Design Spreadsheet

15 April 2019Light-weight Composite Beam Design Spreadsheet

Purpose of calculation:

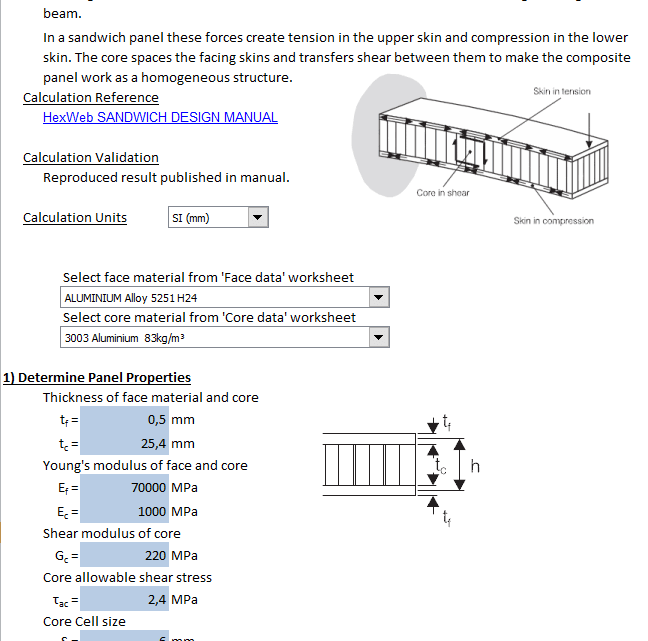

Consider a cantilever beam with a load applied at the free end. The applied load creates a bending moment which is a maximum at the fixed end, and a shear force along the length of the beam. In a sandwich panel these forces create tension in the upper skin and compression in the lower skin. The core spaces the facing skins and transfers shear between them to make the composite panel work as a homogeneous structure.

Calculation Reference

HexWeb SANDWICH DESIGN MANUAL

Calculation Validation

Reproduced result published in manual.

Calculation Procedure

The following face materials can be selected using a drop down combo box (you could also add your own).

- Epoxy UD CARBON tape (0°) 60% volume fraction

- Epoxy UD GLASS tape (0°) 55% volume fraction

- Epoxy WOVEN CARBON (G793-5HS) 55% volume fraction

- Epoxy WOVEN ARAMID (285K-4HS) 60% volume fraction

- Epoxy WOVEN GLASS (7781-8HS) 50% volume fraction

- Phenolic WOVEN GLASS (7781-8HS) 55% volume fraction

- ALUMINIUM Alloy 2024 T3

- ALUMINIUM Alloy 5251 H24

- ALUMINIUM Alloy 6061 T6

- STEEL carbon 1006

- STEEL carbon 1017

- Exterior PLYWOOD Fir

- Tempered HARDWOOD Teak

The following core materials can be selected using a drop down combo box (you could also add your own).

- 3003 Aluminium 29kg/m³

- 3003 Aluminium 37kg/m³

- 3003 Aluminium 42kg/m³

- 3003 Aluminium 54kg/m³

- 3003 Aluminium 59kg/m³

- 3003 Aluminium 83kg/m³

- 5052 Aluminium 37kg/m³

- 5052 Aluminium 50kg/m³

- 5052 Aluminium 54kg/m³

- 5052 Aluminium 72kg/m³

- 5052 Aluminium 83kg/m³

- 5052 Aluminium 127kg/m³

- 5052 Aluminium 130kg/m³

- 5056 Aluminium 37kg/m³

- 5056 Aluminium 50kg/m³

- 5056 Aluminium 50kg/m³

- 5056 Aluminium 72kg/m³

- HRH10 Nomex (Aramid) 29kg/m³

- HRH10 Nomex (Aramid) 32kg/m³

- HRH10 Nomex (Aramid) 32kg/m³

- HRH10 Nomex (Aramid) 48kg/m³

- HRH10 Nomex (Aramid) 48kg/m³

- HRH10 Nomex (Aramid) 64kg/m³

- HRH10 Nomex (Aramid) 64kg/m³

- HRH10 Nomex (Aramid) 80kg/m³

- HRH10 Nomex (Aramid) 96kg/m³

- HRH10 Nomex (Aramid) 123kg/m³

- HRH10 Nomex (Aramid) 144kg/m³

1) Determine Panel Properties

- Thickness of face material and core

- Young’s modulus of face and core

- Shear modulus of core

- Core allowable shear stress

- Core Cell size

- Poisson’s ratio of face

- Limiting stress in face

- Safety Factor

- Poisson’s ratio term

- Distance between face centres

- Critical intracell buckling stress

- Critical face wrinkling stress

- Allowable Tensile Stress on Face

- Panel stiffness coefficient

2) Beam Loading Assessment. The following beam loading conditions can be selected using a drop down combo box:

L1) Simple Support with Uniform Load Distribution

L2) Both Ends Fixed with Uniform Load Distribution

L3) Simple Support with Central Load

L4) Both Ends Fixed with Central Load

L5) Cantilever with Uniform Load Distribution

L6) Cantilever with Load at End

L7) Cantilever with Triangular Load Distribution

- Dimensions of panel

- max shear coefficient

- max bending moment coefficient

- bending deflection coefficient

- shear deflection coefficient

- Total load on beam

- Max bending moment

- Max face stress

- Max shear force

- Core shear stress

- Bending deflection

- Shear deflection

- Total deflection

3) Equivalent plate properties for use with finite element software

It is possible to use the following equivalent plate element properties to match stress and deflection with standard plate elements using finite element analysis software. This should only be done if you can assure that the following conditions are true:

Shear deflections are negligible compared to bending deflections.

Strength of core material is independently checked.

- Equivalent plate thickness for plate element.

- Equivalent Young’s modulus

- Check deflection (note that only deflection due to bending is calculated)

Calculation Reference

Composites Design