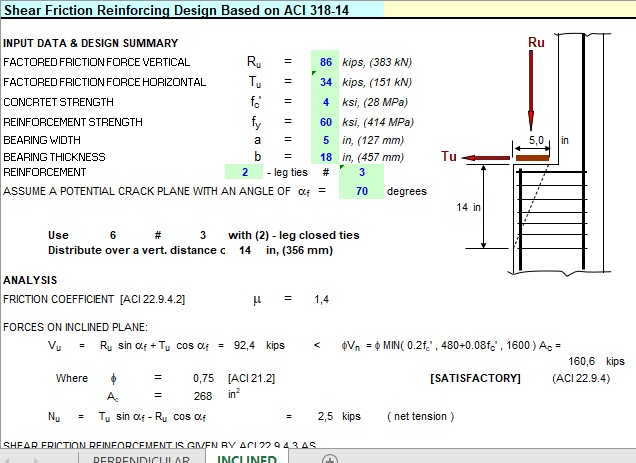

Shear Friction Reinforcing Design Based on ACI 318-14 Spreadsheet

10 December 2022Shear Friction Reinforcing Design Based on ACI 318-14 Spreadsheet

In the world of construction and structural engineering, ensuring the safety and durability of buildings is paramount. One crucial concept that plays a significant role in achieving this is shear friction. This phenomenon is fundamental to the design and performance of various structural elements, particularly when joining concrete components. In this article, we will explore what shear friction is, its significance in construction, and how it is applied to ensure structural integrity.

What Is Shear Friction?

Shear friction is a mechanism by which the interface between two surfaces resists sliding under applied forces. In construction, this typically refers to the interaction between two concrete surfaces or between concrete and other materials, such as steel. When these surfaces are subjected to shear forces, the friction between them, combined with any reinforcement present, prevents them from sliding apart.

This concept is particularly relevant in:

- Concrete-to-concrete joints: Where two concrete components meet, such as a precast slab connecting to a cast-in-place beam.

- Retrofits and repairs: Where new concrete is added to existing structures.

- Steel-concrete interfaces: Common in composite construction, such as steel-reinforced concrete.

The Importance of Shear Friction in Structural Design

Shear friction is critical for several reasons:

- Load Transfer: It ensures that forces are effectively transferred across joint interfaces, maintaining the overall structural integrity.

- Prevention of Structural Failure: By resisting sliding at the interface, shear friction helps prevent shear failure, which could lead to catastrophic collapse.

- Durability: Properly designed shear friction enhances the long-term performance of a structure, reducing maintenance and repair needs.

- Seismic Performance: In earthquake-prone regions, shear friction is a key factor in ensuring that structures can withstand lateral forces.

Factors Influencing Shear Friction

Several factors affect the shear friction capacity of a structure:

- Surface Roughness: Rougher surfaces provide better interlocking and increased friction.

- Clamping Force: Reinforcement, such as steel bars, creates a clamping force that enhances friction.

- Material Properties: The strength of the concrete and steel used directly impacts the overall shear friction.

- Type of Interface: The nature of the joint—whether it is a monolithic pour or a cold joint—also affects performance.

- Presence of Adhesives or Bonding Agents: These can improve the cohesion between surfaces, increasing friction.

How Engineers Design for Shear Friction

Structural engineers use codes and guidelines, such as the American Concrete Institute (ACI) Code, to calculate the required shear friction strength. The process typically involves:

- Determining Shear Force: Calculating the shear forces acting on the joint.

- Assessing Surface Characteristics: Evaluating the roughness and preparation of the interface.

- Reinforcement Design: Specifying the type, size, and placement of reinforcement bars to resist shear.

- Applying Safety Factors: Ensuring the design exceeds minimum requirements to account for uncertainties.

Practical Applications of Shear Friction

- Precast Construction: Ensuring seamless connections between precast components.

- Bridge Construction: Enhancing joint integrity in bridge decks and supports.

- Seismic Retrofitting: Reinforcing existing buildings to meet updated seismic codes.

- Industrial Structures: Providing robust connections in silos, tanks, and other industrial facilities.

Conclusion

Shear friction is an essential principle in construction, playing a critical role in maintaining the stability and safety of structures. By understanding and effectively applying this concept, engineers can design buildings and infrastructure that stand the test of time and natural forces. Whether you’re constructing a new skyscraper or retrofitting an older structure, shear friction remains a cornerstone of structural engineering.

To stay ahead in the construction industry, it is vital to keep up with advancements in materials and techniques that improve shear friction performance. By prioritizing this aspect of design, we can ensure a safer, more resilient built environment for generations to come.