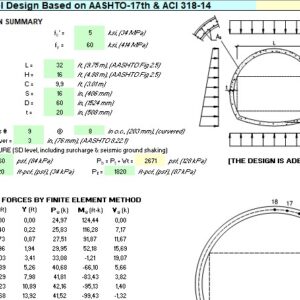

Spreadsheet for Concrete Tunnel Design and Calculations According to AASHTO and ACI Standards

In the realm of civil engineering, designing concrete tunnels involves intricate calculations and adherence to stringent standards. To streamline this complex process, we are excited to introduce a powerful and user-friendly spreadsheet designed for concrete tunnel design and calculations in compliance with AASHTO (American Association of State Highway and Transportation Officials) and ACI (American Concrete Institute) standards.

Why a Concrete Tunnel Design Spreadsheet?

Concrete tunnel design is a multifaceted task that requires meticulous attention to detail. Engineers must consider various factors such as load-bearing capacity, structural integrity, safety measures, and compliance with regulatory standards. Traditional methods of manual calculations can be time-consuming and prone to errors. Our spreadsheet solution addresses these challenges by providing an automated, reliable, and efficient tool that simplifies the design process while ensuring accuracy and compliance.

Key Features of the Spreadsheet

- Compliance with AASHTO and ACI Standards

- The spreadsheet is built to adhere to the latest guidelines and specifications set forth by AASHTO and ACI. This ensures that your tunnel designs meet the required safety and performance standards, providing peace of mind and regulatory compliance.

- User-Friendly Interface

- Designed with engineers in mind, the spreadsheet features an intuitive interface that allows for easy data entry and navigation. Even those with limited experience in tunnel design can quickly get up to speed and produce reliable results.

- Comprehensive Design Calculations

- The spreadsheet performs a wide range of calculations necessary for concrete tunnel design, including:

- Load analysis: Evaluating the effects of various loads, such as live loads, dead loads, and environmental loads.

- Structural analysis: Determining the stress distribution, bending moments, and shear forces within the tunnel structure.

- Reinforcement design: Calculating the required reinforcement for both longitudinal and transverse directions.

- Stability checks: Assessing the overall stability of the tunnel structure under different loading conditions.

- The spreadsheet performs a wide range of calculations necessary for concrete tunnel design, including:

- Automated Reporting

- Generate detailed reports that outline the design assumptions, calculation results, and compliance checks. These reports can be easily shared with stakeholders and regulatory bodies, facilitating transparent communication and documentation.

- Customizable Templates

- The spreadsheet comes with customizable templates that allow engineers to tailor the design parameters to specific project requirements. Whether you are working on a highway tunnel, a railway tunnel, or an underground passageway, the templates can be adjusted to fit your needs.

- Real-Time Error Checking

- Built-in error-checking mechanisms alert users to potential issues and inconsistencies in their input data. This proactive feature helps to identify and correct errors early in the design process, saving time and reducing the risk of costly mistakes.