Types and Causes of Concrete Deterioration

19 November 2018Table of Contents

Types and Causes of Concrete Deterioration

The exceptional durability of portland cement concrete is a major reason why it is the world’s most widely used construction material. But material limitations, design and construction practices, and severe exposure conditions can cause concrete to deteriorate, which may result in aesthetic, functional, or structural problems.

Concrete can deteriorate for a variety of reasons, and concrete damage is often the result of a combination of factors. The following summary discusses potential causes of concrete deterioration and the factors that influence them.

1. CORROSION OF EMBEDDED METALS

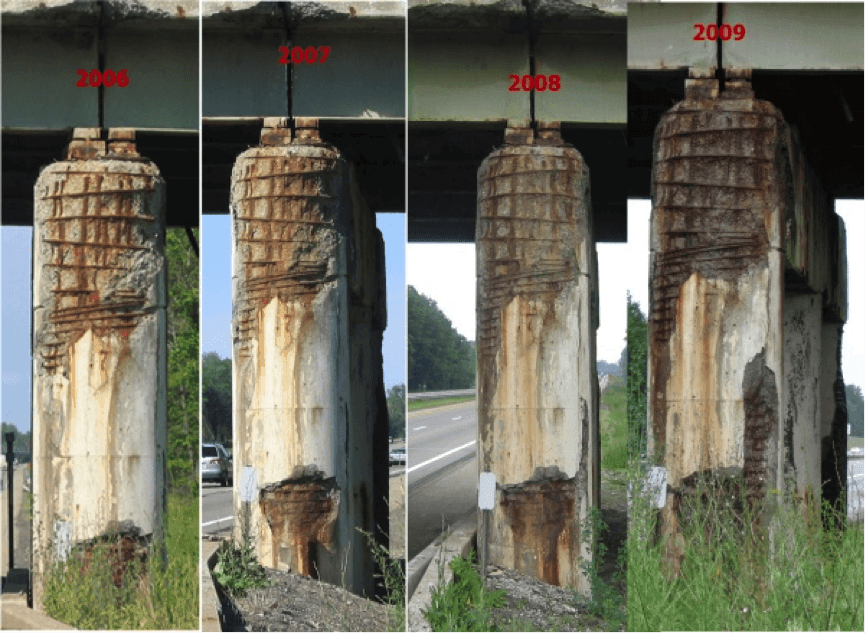

Corrosion of reinforcing steel and other embedded metals is the leading cause of deterioration in concrete. When steel corrodes, the resulting rust occupies a greater volume than the steel. This expansion creates tensile stresses in the concrete, which can eventually cause cracking, delamination, and spalling (Figs. 1 and 2).

Fig. 1. Corrosion of reinforcing steel is the most common cause of concrete deterioration.

Fig. 2. The expansion of corroding steel creates tensile stresses in the concrete, which can cause cracking,

delamination, and spalling.

Steel corrodes because it is not a naturally occurring material.Rather, iron ore is smelted and refined to produce steel. The production steps that transform iron ore into steel add energy to the metal. Steel, like most metals except gold and platinum, is thermodynamically unstable under normal atmospheric conditions and will release energy and revert back to its natural state — iron oxide, or rust. This process is called corrosion.

For corrosion to occur, four elements must be present: There must be at least two metals (or two locations on a single metal) at different energy levels, an electrolyte, and a metallic connection. In reinforced concrete, the rebar may have many separate areas at different energy levels. Concrete acts as the electrolyte, and the metallic connection is provided by wire ties, chair supports, or the rebar itself.

a – Concrete and the Passivating Layer

Although steel’s natural tendency is to undergo corrosion reactions, the alkaline environment of concrete (pH of 12 to 13) provides steel with corrosion protection. At the high pH, a thin oxide layer forms on the steel and prevents metal atoms from dissolving. This passive film does not actually stop corrosion; it reduces the corrosion rate to an insignificant level. For steel in concrete, the passive corrosion rate is typically 0.1 μm per year.

Without the passive film, the steel would corrode at rates at least 1,000 times higher (ACI 222 2001). Because of concrete’s inherent protection, reinforcing steel does not corrode in the majority of concrete elements and structures.

However, corrosion can occur when the passivating layer is destroyed. The destruction of the passivating layer occurs when the alkalinity of the concrete is reduced or when the chloride concentration in concrete is increased to a certain level.

b – The Role of Chloride Ions

Exposure of reinforced concrete to chloride ions is the primary cause of premature corrosion of steel reinforcement. The intrusion of chloride ions, present in deicing salts and seawater, into reinforced concrete can cause steel corrosion if oxygen and moisture are also available to sustain the reaction (Fig. 3). Chlorides dissolved in water can permeate

through sound concrete or reach the steel through cracks.

Fig. 3. Deicing salts are a major cause of corrosion of reinforcing steel in concrete.

Chloride-containing admixtures can also cause corrosion. No other contaminant is documented as extensively in the literature as a cause of corrosion of metals in concrete than chloride ions. The mechanism by which chlorides promote corrosion is not entirely understood, but the most popular theory is that chloride ions penetrate the protective oxide film easier than do other ions, leaving the steel vulnerable to corrosion.

c – Carbonation

Carbonation occurs when carbon dioxide from the air penetrates the concrete and reacts with hydroxides, such as calcium hydroxide, to form carbonates. In the reaction with calcium hydroxide, calcium carbonate is formed:

Ca(OH)2 + CO2 → CaCO3 + H2O

This reaction reduces the pH of the pore solution to as low as 8.5, at which level the passive film on the steel is not stable. Carbonation is generally a slow process. In high-quality concrete, it has been estimated that carbonation will proceed at a rate up to 1.0 mm (0.04 in.) per year. The amount of carbonation is significantly increased in concrete with a high water-to-cement ratio, low cement content, short curing period, low strength, and highly permeable or porous paste.

Carbonation is highly dependent on the relative humidity of the concrete. The highest rates of carbonation occur when the relative humidity is maintained between 50% and 75%. Below 25% relative humidity, the degree of carbonation that takes place is considered insignificant. Above 75% relative humidity, moisture in the pores restricts CO2 penetration (ACI 201 1992).

Carbonation-induced corrosion often occurs on areas of building facades that are exposed to rainfall, shaded from sunlight, and have low concrete cover over the reinforcing steel (Fig. 5).

Fig. 4. Carbonation-induced corrosion often occurs on building facades with shallow concrete cover.

d – Dissimilar Metal Corrosion

When two different metals, such as aluminum and steel, are in contact within concrete, corrosion can occur because each metal has a unique electrochemical potential. A familiar type of dissimilar metal corrosion occurs in an ordinary flashlight battery. The zinc case and carbon rod are the two metals, and the moist paste acts as the electrolyte. When the carbon and zinc are connected by a wire, current flows. In reinforced concrete, dissimilar metal corrosion can occur in balconies where embedded aluminum railings are in contact with the reinforcing steel.

Below is a list of metals in order of electrochemical activity:

Zinc / Aluminum / Steel / Iron / Nickel / Tin / Lead / Brass / Copper / Bronze / Stainless Steel / Gold

When the metals are in contact in an active electrolyte, the less active metal (lower number) in the series corrodes.

2. FREEZE-THAW DETERIORATION

When water freezes, it expands about 9%. As the water in moist concrete freezes, it produces pressure in the capillaries and pores of the concrete. If the pressure exceeds the tensile strength of the concrete, the cavity will dilate and rupture. The accumulative effect of successive freeze-thaw cycles and disruption of paste and aggregate can eventually cause significant expansion and cracking, scaling, and crumbling of the concrete (Fig. 5).

The resistance of concrete to freezing and thawing in a moist condition is significantly improved by the use of intentionally entrained air. Entrained air voids act as empty chambers in the paste for the freezing and migrating water to enter, thus relieving the pressure in the capillaries and pores and preventing damage to the concrete.

Concrete with low permeability is also better able resist the penetration of water and, as a result, performs better when

exposed to freeze-thaw cycles. The permeability of concrete is directly related to its water-to-cement ratio—the lower the water-to-cement ratio, the lower the permeability of the concrete.

Fig 5. Freeze-thaw cycles can cause scaling of concrete surfaces

a – Deicer Scaling

Deicing chemicals used for snow and ice removal, such as sodium chloride, can aggravate freeze-thaw deterioration. The additional problem caused by deicers is believed to be a buildup of osmotic and hydraulic pressures in excess of the normal hydraulic pressures produced when water in concrete freezes. In addition, because salt absorbs moisture, it keeps the concrete more saturated, increasing the potential for freeze-thaw deterioration. However, properly designed and placed air-entrained concrete can withstand deicers for many years.

In the absence of freezing, sodium chloride has little to no chemical effect on concrete. Weak solutions of calcium chloride generally have little chemical effect on concrete, but studies have shown that concentrated calcium chloride solutions can chemically attack concrete. Magnesium chloride deicers have come under recent criticism for aggravating scaling. One study found that magnesium chloride, magnesium acetate, magnesium nitrate, and calcium chloride are more damaging to concrete than sodium chloride (Cody, Cody, Spry, and Gan 1996). Deicers containing ammonium nitrate and ammonium sulfate should be prohibited because they rapidly attack and disintegrate concrete.

b – Aggregate Expansion

Some aggregates may absorb so much water (to critical saturation) that they cannot accommodate the expansion and

hydraulic pressure that occurs during the freezing of water. The result is expansion of the aggregate and possible disintegration of the concrete if enough of the offending particles are present. If a problem particle is near the surface of the concrete, it can cause a popout.

D-cracking is a form of freeze-thaw deterioration that has been observed in some pavements after three or more years of service. Due to the natural accumulation of water in the base and subbase of pavements, the aggregate may eventually become saturated. Then with freezing and thawing cycles, cracking of the concrete starts in the saturated aggregate at the bottom of the slab and progresses upward until it reaches the wearing surface. D-cracking usually starts near pavement joints.

Aggregate freeze-thaw problems can often be reduced by either selecting aggregates that perform better in freeze-thaw cycles or, where marginal aggregates must be used, reducing the maximum particle size.

Fig 6. D-cracking is a form of freeze-thaw deterioration that has been observed in some pavements after three or more

years of service.

3. CHEMICAL ATTACK

Concrete performs well when exposed to various atmospheric conditions, water, soil, and many other chemical exposures. However, some chemical environments can deteriorate even high-quality concrete. Concrete is rarely, if ever, attacked by solid, dry chemicals. To produce significant attack on concrete, aggressive chemicals must be in solution and above some minimum concentration.

a – Acids

In general, portland cement concrete does not have good resistance to acids. In fact, no hydraulic cement concrete, regardless of its composition, will hold up for long if exposed to a solution with a pH of 3 or lower. However, some weak acids can be tolerated, particularly if the exposure is occasional.

Acids react with the calcium hydroxide of the hydrated portland cement. In most cases, the chemical reaction forms water-soluble calcium compounds, which are then leached away by aqueous solutions (ACI 201 1992).

The products of combustion of many fuels contain sulfurous gases which combine with moisture to form sulfuric acid. Also, certain bacteria convert sewage into sulfuric acid. Sulfuric acid is particularly aggressive to concrete because the calcium sulfate formed from the acid reaction will also deteriorate concrete via sulfate attack (Fig. 7).

Fig. 7. Bacteria in sewage systems can produce sulfuric acid, which aggressively attacks concrete

In addition to individual organic and mineral acids which may attack concrete, acid-containing or acid-producing substances, such as acidic industrial wastes, silage, fruit juices, and sour milk, will also cause damage.

Animal wastes contain substances which may oxidize in air to form acids which attack concrete. The saponification reaction between animal fats and the hydration products of portland cement consumes these hydration products, producing salts and alcohols, in a reaction analogous to that of acids. Acid rain, which often has a pH of 4 to 4.5, can slightly etch concrete, usually without affecting the performance of the exposed surface.

Any water that contains bicarbonate ion also contains free carbon dioxide, a part of which can dissolve calcium carbonate unless saturation already exists. This part is called the “aggressive carbon dioxide.” Water with aggressive carbon dioxide acts by acid reaction and can attack concrete and other portland cement products whether or not they are carbonated.

Calcium-absorptive acidic soil can attack concrete, especially porous concrete. Even slightly acidic solutions that are lime-deficient can attack concrete by dissolving calcium from the paste, leaving behind a deteriorated paste consisting primarily of silica gel.

To prevent deterioration from acid attack, portland cement concrete generally must be protected from acidic environments with surface protective treatments. Unlike limestone and dolomitic aggregates, siliceous aggregates are acid-resistant and are sometimes specified to improve the chemical resistance of concrete, especially with the use of chemical-resistant cement. Properly cured concrete with reduced permeability experience a slightly lower rate of attack from acids.

b – Salts and Alkalis

The chlorides and nitrates of ammonium, magnesium, aluminum, and iron all cause concrete deterioration, with those of ammonium producing the most damage. Most ammonium salts are destructive because, in the alkaline environment of concrete, they release ammonia gas and hydrogen ions. These are replaced by dissolving calcium hydroxide from the concrete. The result is a leaching action, much like acid attack. Strong alkalies (over 20 percent) can also cause concrete disintegration (ACI 515 1979).

c – Sulfate Attack

Naturally occurring sulfates of sodium, potassium, calcium, or magnesium are sometimes found in soil or dissolved in ground-water. Sulfates can attack concrete by reacting with hydrated compounds in the hardened cement. These reactions can induce sufficient pressure to disrupt the cement paste, resulting in loss of cohesion and strength.

Calcium sulfate attacks calcium aluminate hydrate and forms ettringite. Sodium sulfate reacts with calcium hydroxide and calcium aluminate hydrate forming ettringite and gypsum. Magnesium sulfate attacks in a manner similar to sodium sulfate and forms ettringite, gypsum, and brucite (magnesium hydroxide). Brucite forms primarily on the concrete surface, consumes calcium hydroxide, lowers the pH of the pore solution, and then decomposes the calcium silicate hydrates.

Environmental conditions have a great influence on sulfate attack. The attack is greater in concrete exposed to wet/dry

cycling (Fig. 8). When water evaporates, sulfates can accumulate at the concrete surface, increasing in concentration

and their potential for causing deterioration.

Fig 8. The bases of these concrete posts have suffered from sulfate attack

Porous concrete is susceptible to weathering caused by salt crystallization. Examples of salts known to cause weathering of field concrete include sodium carbonate and sodium sulfate (laboratory studies have also related saturated solutions of calcium chloride and other salts to concrete deterioration). Under drying conditions, salt solutions can rise to the surface by capillary action and, as a result of surface evaporation, the solution phase

becomes supersaturated and salt crystallization occurs, sometimes generating pressures large enough to cause cracking and scaling (Mehta 2000).

Sulfate attack is a particular problem in arid areas, such as the Northern Great Plains and parts of the Western United States. Seawater also contains sulfates but is not as severe an exposure as sulfates in groundwater.

4. ALKALI-AGGREGATE REACTIVITY

In most concrete, aggregates are more or less chemically inert. However, some aggregates react with the alkali hydroxides in concrete, causing expansion and cracking over a period of years. This alkali-aggregate reactivity has two forms—alkali-silica reaction (ASR) and alkali-carbonate reaction (ACR). ASR is of more concern than ACR because aggregates containing reactive silica materials are more common.

a – Alkali-Silica Reactivity

Aggregates containing certain forms of silica will react with alkali hydroxide in concrete to form a gel that swells as it draws water from the surrounding cement paste or the environment. In absorbing water, these gels can swell and induce enough expansive pressure to damage concrete:

1. Alkalies + Reactive Silica → Gel Reaction Product

2. Gel Reaction Product + Moisture → Expansion

Typical indicators of alkali-silica reactivity are map (random pattern) cracking and, in advanced cases, closed joints and spalled concrete surfaces (Fig. 9). Cracking usually appears in areas with a frequent supply of moisture, such as close to the waterline in piers, from the ground behind retaining walls, near joints and free edges in pavements, or in piers or columns subject to wick action.

Because sufficient moisture is needed to promote destructive expansion, alkali-silica reactivity can be significantly reduced by keeping the concrete as dry as possible. The reactivity can be virtually stopped if the internal relative humidity of the concrete is kept below 80%. In most cases, however, this condition is difficult to achieve and maintain. Warm seawater, due to the presence of dissolved alkalies, can particularly aggravate alkali-silica reactivity.

Fig. 9. Typical indicators of alkali-silica reactivity are map cracking and, in advanced cases, closed joints and spalled

concrete surfaces

b – Alkali-Carbonate Reactivity

Reactions observed with certain dolomitic rocks are associated with alkali-carbonate reaction (ACR). Dedolomitization, or the breaking down of dolomite, is normally associated with expansive alkali-carbonate reactivity. This reaction and subsequent crystallization of brucite may cause considerable expansion.

The deterioration caused by alkali-carbonate reaction is similar to that caused by alkali-silica reaction (Fig. 10); however, alkali-carbonate reaction is relatively rare because aggregates susceptible to this reaction are less common and are usually unsuitable for use in concrete for other reasons, such as strength potential.

Fig. 10. Map cracking pattern caused by alkali-carbonate reactivity.

5. ABRASION/EROSION

Abrasion damage occurs when the surface of concrete is unable to resist wear caused by rubbing and friction. As the outer paste of concrete wears, the fine and coarse aggregate are exposed and abrasion and impact will cause additional degradation that is related to aggregate-to-paste bond strength and hardness of the aggregate.

Although wind-borne particles can cause abrasion of concrete, the two most damaging forms of abrasion occur on vehicular traffic surfaces and in hydraulic structures, such as dams, spillways, and tunnels.

a – Traffic Surfaces

Abrasion of floors and pavements may result from production operations or vehicular traffic. Many industrial floors are subjected to abrasion by steel or hard rubber wheeled traffic, which can cause significant rutting.

Tire chains and studded snow tires cause considerable wear to concrete surfaces (Fig. 11). In the case of tire chains, wear is caused by flailing and scuffing as the rotating tire brings the metal in contact with the concrete surface.

Fig 11. Tire chains and studded snow tires can cause considerable wear to concrete surfaces

b – Hydraulic Structures

Abrasion damage in hydraulic structures is caused by the abrasive effects of waterborne silt, sand, gravel, rocks, ice, and other debris impinging on the concrete surface. Although high-quality concrete can resist high water velocities for many years with little or no damage, the concrete may not withstand the abrasive action of debris grinding or repeatedly impacting on its surface.

In such cases, abrasion erosion ranging from a few millimeters (inches) to several meters (feet) can result, depending on flow conditions. Spillway aprons, stilling basins, sluiceways, drainage conduits or culverts, and tunnel linings are particularly susceptible to abrasion erosion. Abrasion erosion is readily recognized by its smooth, worn appearance, which is distinguished from the small holes and pits formed by cavitation erosion.

As is the case with traffic wear, abrasion damage in hydraulic structures can be reduced by using strong concrete with hard aggregates. Cavitation is the formation of bubbles or cavities in a liquid. In hydraulic structures, the liquid is water and the cavities are filled with water vapor and air. The cavities form where the local pressure drops to a value that will cause the water to vaporize at the prevailing fluid temperature. Cavitation damage is produced when the vapor cavities collapse, causing very high instantaneous pressures that impact on the concrete surfaces, causing pitting, noise, and vibration.

6. FIRE/HEAT

Concrete performs exceptionally well at the temperatures encountered in almost all applications. But when exposed to fire or unusually high temperatures, concrete can lose strength and stiffness (Fig. 12).

Fig. 12. When exposed to fire or unusually high temperatures, concrete can lose strength and stiffness

Numerous studies have found the following general trends:

• Concrete that undergoes thermal cycling suffers greater loss of strength than concrete that is held at a constant temperature, although much of the strength loss occurs in the first few cycles. This is attributed to incompatible dimensional changes between the cement paste and the aggregate.

• Concrete that is under design load while heated loses less strength than unloaded concrete, the theory being that

imposed compressive stresses inhibit development of cracks that would be free to develop in unrestrained concrete.

• Concrete that is allowed to cool before testing loses more compressive strength than concrete that is tested hot. Concrete loses more strength when quickly cooled (quenched) from high temperatures than when it is allowed to cool

gradually.

• Concrete containing limestone and calcareous aggregates performs better at high temperatures than concrete containing siliceous aggregates (Abrams 1956). One study showed no difference in the performance of dolostone and limestone (Carette 1982). Another study showed the following relative aggregate performance, from best to worst: firebrick, expanded shale, limestone, gravel, sandstone and expanded slag.

• Proportional strength loss is independent of compressive strength of concrete.

• Concrete with a higher aggregate-cement ratio suffers less reduction in compressive strength; however, the opposite is true for modulus of elasticity. The lower the water-cement ratio, the less loss of elastic modulus.

• If residual water in the concrete is not allowed to evaporate, compressive strength is greatly reduced. If heated too quickly, concrete can spall as the moisture tries to escape.

7. RESTRAINT TO VOLUME CHANGES

Concrete changes slightly in volume for various reasons, the most common causes being fluctuations in moisture content and temperature. Restraint to volume changes, especially contraction, can cause cracking if the tensile stresses that develop exceed the tensile strength of the concrete.

a – Plastic Shrinkage Cracking

When water evaporates from the surface of freshly placed concrete faster than it is replaced by bleed water, the surface concrete shrinks. Due to the restraint provided by the concrete below the drying surface layer, tensile stresses develop in the weak, stiffening plastic concrete, resulting in shallow cracks of varying depth (Fig. 12). These cracks are often fairly wide at the surface.

Fig. 13. Plastic shrinkage cracks can occur when water evaporates from the surface faster than it is replaced by bleedwater

Plastic shrinkage cracks can be prevented by taking measures to prevent rapid water loss from the concrete surface. Fog nozzles, plastic sheeting, windbreaks, and sunshades can all be used to prevent excessive evaporation.

b – Drying Shrinkage Cracking

Because almost all concrete is mixed with more water than is needed to hydrate the cement, much of the remaining water evaporates, causing the concrete to shrink. Restraint to shrinkage, provided by the subgrade, reinforcement, or another part of the structure, causes tensile stresses to develop in the hardened concrete. Restraint to drying shrinkage is the most common cause of concrete cracking.

In many applications, drying shrinkage cracking is inevitable. Therefore, control joints are placed in concrete to predetermine the location of drying shrinkage cracks. Drying shrinkage can be limited by keeping the water content of concrete as low as possible and maximizing the coarse aggregate content.

c – Thermal Cracking

Concrete expands when heated and contracts when cooled. An average value for the thermal expansion of concrete is about 10 millionths per degree Celcius (5.5 millionths per degree Fahrenheit). This amounts to a length change of 5 mm for 10 m of concrete ( 2 ⁄ 3 in. for 100 ft of concrete) subjected to a rise or fall of 50°C (90°F).

Thermal expansion and contraction of concrete varies with factors such as aggregate type, cement content, water-cement ratio, temperature range, concrete age, and relative humidity. Of these, aggregate type has the greatest influence.

Designers should give special consideration to structures in which some portions of the structure are exposed to temperature changes, while other portions are partially or completely protected. Allowing for movement by using properly designed expansion or isolation joints and correct detailing will help minimize the effects of temperature variations.