TYPES OF CONCRETE BLOCKS OR CONCRETE MASONRY UNITS IN CONSTRUCTION

8 November 2019Table of Contents

TYPES OF CONCRETE BLOCKS OR CONCRETE MASONRY UNITS IN CONSTRUCTION

Concrete block masonry which is also known as concrete masonry unit (CMU) have advantages over brick and stone masonry. Concrete blocks are manufactured in required shape and sizes and these may be solid or hollow blocks. The common size of concrete blocks is 39cm x 19cm x (30cm or 20 cm or 10cm) or 2 inch, 4 inch, 6 inch, 8 inch, 10 inch and 12-inch unit configurations.

Cement, aggregate, water is used to prepare concrete blocks. The cement-aggregate ratio in concrete blocks is 1:6. Aggregate used is of 60% fine aggregate and 40% coarse aggregate. Their Minimum strength is about 3N/mm2. ASTM C-90-91 specifies the compressive strength requirements of concrete masonry units.

Types of Concrete Blocks or Concrete Masonry Units

Depending upon the structure, shape, size and manufacturing processes concrete blocks are mainly classified into 2 types and they are

- Solid concrete blocks

- Hollow concrete Blocks

Solid Concrete Blocks

Solid concrete blocks are commonly used, which are heavy in weight and manufactured from dense aggregate. They are very strong and provides good stability to the structures. So for large work of masonry like for load bearing walls these solid blocks are preferable.

They are available in large sizes compared to bricks. So, it takes less time to construct concrete masonry than brick masonry.

Fig.1 – Solid Concrete Blocks

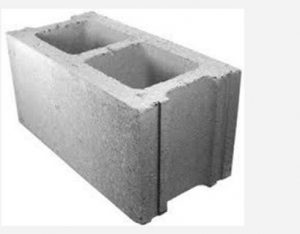

Hollow Concrete Blocks

Hollow concrete blocks contains void area greater than 25% of gross area. Solid area of hollow bricks should be more than 50%. The hollow part may be divided into several components based on our requirement. They are manufactured from lightweight aggregates. They are light weight blocks and easy to install.

Types of Hollow Concrete Blocks:

- Stretcher block

- Corner block

- Pillar block

- Jamb block

- Partition block

- Lintel block

- Frogged brick block

- Bull nose block

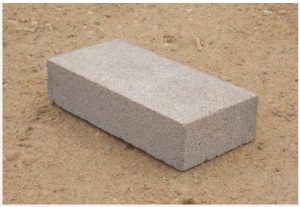

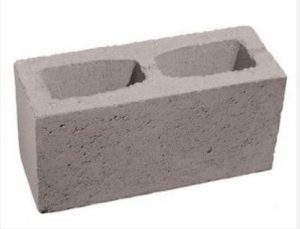

Concrete Stretcher Blocks

Concrete stretcher blocks are used to join the corner in the masonry. Stretcher blocks are widely used concrete hollow blocks in construction. They are laid with their length parallel to the face of the wall.

Fig.2 – Concrete Stretcher Blocks

Concrete Corner Blocks

Corner blocks are used at the ends or corners of masonry. The ends may be window or door openings etc. they are arranged in a manner that their plane end visible to the outside and other end is locked with the stretcher block.

Fig.3 – Concrete Corner Blocks

Concrete Pillar Blocks

Pillar block is also called as double corner block. Generally these are used when two ends of the corner are visible. In case of piers or pillars these blocks are widely used.

Fig.4 – Concrete Pillar Blocks

Jamb Concrete Blocks

Jamb blocks are used when there is an elaborated window opening in the wall. They are connected to stretcher and corner blocks. For the provision of double hung windows, jamb blocks are very useful to provide space for the casing members of window.

Fig.5 – Jamb Concrete Blocks

Partition Concrete Block

Partition concrete blocks are generally used to build partition walls. Partition blocks have larger height than its breadth. Hollow part is divided into two to three components in case of partition blocks.

Fig.6 – Partition Concrete Block

Lintel Blocks

Lintel block or beam block is used for the purpose of provision of beam or lintel beam. Lintel beam is generally provided on the top portion of doors and windows, which bears the load coming from top. Concrete lintel blocks have deep groove along the length of block as shown in figure. After placing the blocks, this groove is filled with concrete along with reinforcement.

Fig.7 – Lintel Blocks

Frogged Brick Blocks

Frogged brick block contains a frog on its top along with header and stretcher like frogged brick. This frog will helps the block to hold mortar and to develop the strong bond with top laying block.

Fig.8 – Frogged Bricks Blocks

Bullnose Concrete Block

Bullnose blocks are similar to corner blocks. Their duties also same but when we want rounded edges at corner bullnose bricks are preferred.

Fig.9 – Bullnose Concrete Block