Types of Concrete Gravity Dams

24 December 2019Table of Contents

Types of Concrete Gravity Dams

Introduction

Gravity dams are solid concrete structures that maintain their stability against design loads from the geometric shape and the mass and strength of the concrete. Generally, they are constructed on a straight axis,

but may be slightly curved or angled to accommodate the specific site conditions.

Gravity dams typically consist of a nonoverflow section(s) and an overflow section or spillway. The two general concrete construction methods for concrete gravity dams are conventional placed mass concrete and RCC.

1. Conventional concrete dams

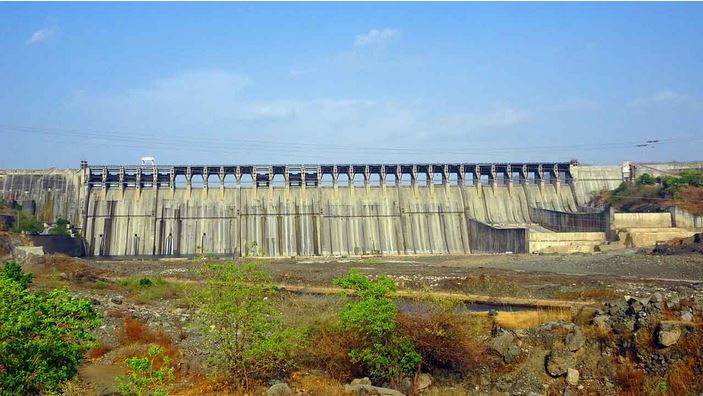

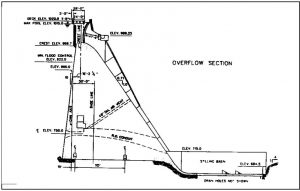

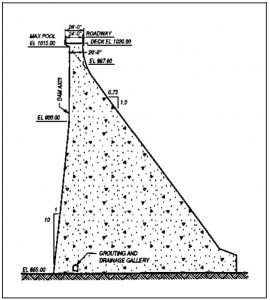

Conventionally placed mass concrete dams are characterized by construction using materials and techniques employed in the proportioning, mixing, placing, curing, and temperature control of mass concrete (American Concrete Institute (ACI) 207.1 R-87). Typical overflow and nonoverflow sections are shown on Figures 1 and 2.

Figure 1 : Typical dam overflow section

Figure 2 : Nonoverflow section

Construction incorporates methods that have been developed and perfected over many years of designing and building mass concrete dams. The cement hydration process of conventional concrete limits the size and rate of concrete placement and necessitates building in monoliths to meet crack control requirements.

Generally using large-size coarse aggregates, mix proportions are selected to produce a low-slump concrete that gives economy, maintains good workability during placement, develops minimum temperature rise during hydration, and produces important properties such as strength, impermeability, and durability. Dam construction with conventional concrete readily facilitates installation of conduits, penstocks, galleries, etc., within the structure.

Construction procedures include batching and mixing, and transportation, placement, vibration, cooling, curing, and preparation of horizontal construction joints between lifts.

The large volume of concrete in a gravity dam normally justifies an onsite batch plant, and requires an aggregate source of adequate quality and quantity, located at or within an economical distance of the project.

Transportation from the batch plant to the dam is generally performed in buckets ranging in size from 4 to 12 cubic yards carried by truck, rail, cranes, cableways, or a combination of these methods. The maximum bucket size is usually restricted by the capability of effectively spreading and vibrating the concrete pile after it is dumped from the bucket. The concrete is placed in lifts of 5- to 10-foot depths. Each lift consists of successive layers not exceeding 18 to 20 inches. Vibration is generally performed by large one-man, air-driven, spud-type vibrators.

Methods of cleaning horizontal construction joints to remove the weak laitance film on the surface during curing include green cutting, wet sand-blasting, and high-pressure air-water jet. Additional details of conventional concrete placements are covered in EM 1110-2-2000.

The heat generated as cement hydrates requires careful temperature control during placement of mass concrete and for several days after placement. Uncontrolled heat generation could result in excessive tensile stresses due to extreme gradients within the mass concrete or due to temperature reductions as the concrete approaches its annual temperature cycle.

Control measures involve precooling and postcooling techniques to limit the peak temperatures and control the temperature drop. Reduction in the cement content and cement replacement with pozzolans have reduced the temperature-rise potential. Crack control is achieved by constructing the conventional concrete gravity dam in a series of individually stable monoliths separated by transverse contraction joints.

2. Roller-compacted concrete (RCC) gravity dams

The design of RCC gravity dams is similar to conventional concrete structures. The differences lie in the construction methods, concrete mix design, and details of the appurtenant structures. Construction of an RCC dam is a relatively new and economical concept.

Economic advantages are achieved with rapid placement using construction techniques that are similar to those employed for embankment dams. RCC is a relatively dry, lean, zero slump concrete material containing coarse and fine aggregate that is consolidated by external vibration using vibratory rollers, dozer, and other heavy equipment.

In the hardened condition, RCC has similar properties to conventional concrete. For effective consolidation, RCC must be dry enough to support the weight of the construction equipment, but have a consistency wet enough to permit

adequate distribution of the past binder throughout the mass during the mixing and vibration process and, thus,

achieve the necessary compaction of the RCC and prevention of undesirable segregation and voids.