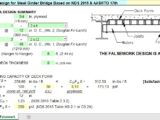

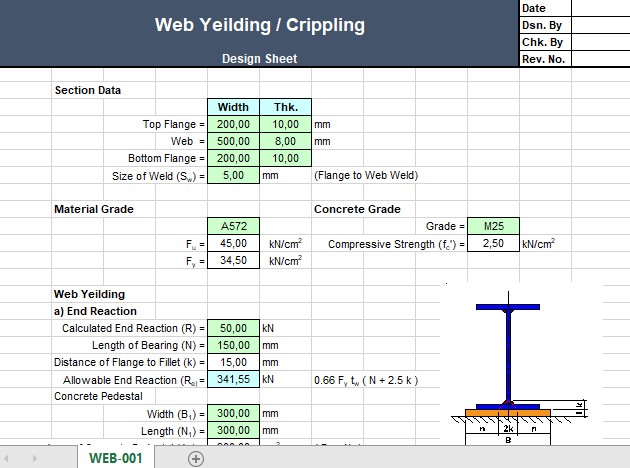

Web Yeilding and Crippling Design Spreadsheet

11 June 2022Web Yeilding and Crippling Design Spreadsheet

In the construction industry, structural integrity is paramount. Engineers and builders must ensure that every component of a structure can handle the loads and stresses it encounters. Among the critical considerations are web yielding and web crippling—terms often associated with the design and analysis of structural elements, particularly beams and columns. This article delves into what these phenomena mean, their causes, and how they can be mitigated.

What is Web Yielding?

Web yielding refers to the localized failure that occurs when the web of a structural member, such as a steel I-beam, is subjected to excessive stress. This phenomenon typically arises at points of concentrated loads or reactions, where the web—the thin vertical section connecting the flanges of the beam—bears high compressive stresses.

Key Causes of Web Yielding:

- Concentrated Loads: Heavy loads applied at a single point can overwhelm the web.

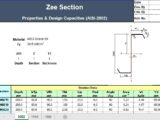

- Insufficient Web Thickness: Thin webs are more susceptible to yielding under stress.

- Poor Material Quality: Substandard materials with low yield strength can lead to early failure.

Why It Matters: Web yielding compromises the load-carrying capacity of the structural member, potentially leading to deformations or even catastrophic failure. Identifying and mitigating this issue is crucial during the design phase.

What is Web Crippling?

Web crippling occurs when localized compressive forces cause the web of a structural member to buckle or deform. Unlike web yielding, which is associated with stress exceeding material yield strength, web crippling is a geometric instability phenomenon.

Key Causes of Web Crippling:

- High Localized Forces: Concentrated loads near supports or at edges can trigger crippling.

- Unsupported Webs: Webs without stiffeners or reinforcements are more prone to buckling.

- Large Hole Openings: Webs with cutouts for utilities weaken the overall structure.

Why It Matters: Web crippling can lead to sudden and severe failures, endangering the structural integrity and safety of the project. It is often a critical concern in lightweight and thin-walled structures.

Differences Between Web Yielding and Web Crippling

While both phenomena affect the web of a structural member, they are fundamentally different:

- Web Yielding is stress-related and occurs when the material strength is exceeded.

- Web Crippling is geometry-related and happens due to instability under compressive forces.

Solutions to Prevent Web Yielding and Crippling

Addressing web yielding and crippling requires a combination of thoughtful design, high-quality materials, and practical construction techniques.

1. Increase Web Thickness: Using thicker webs can distribute stresses more evenly, reducing the risk of both yielding and crippling.

2. Add Stiffeners: Installing vertical or diagonal stiffeners strengthens the web, preventing buckling and enhancing load resistance.

3. Optimize Load Distribution: Avoid concentrated loads by spreading forces over larger areas through bearing plates or load distribution pads.

4. Use High-Strength Materials: Selecting materials with higher yield strength ensures that the web can handle greater stresses without deforming.

5. Conduct Detailed Analysis: Advanced software tools, such as finite element analysis (FEA), can predict stress concentrations and potential failure points.

6. Follow Design Standards: Adhere to design codes like the American Institute of Steel Construction (AISC) or Eurocode for specific guidelines on web design.

Real-World Applications

Web yielding and crippling are critical considerations in industries such as:

- Bridge Construction: Ensuring that beams can handle heavy vehicular loads without failing.

- Building Design: Supporting multi-story buildings with robust structural frameworks.

- Industrial Facilities: Designing for heavy equipment and machinery loads.

Conclusion

Web yielding and crippling are vital concepts in structural engineering that directly impact the safety and performance of construction projects. By understanding these phenomena and implementing preventive measures, engineers can design structures that stand the test of time. Whether through increased web thickness, stiffeners, or advanced design tools, addressing these issues ensures both safety and efficiency in construction.

For professionals in the field, staying informed and leveraging cutting-edge technology is the key to mastering these challenges. By prioritizing structural integrity, we can build safer and more reliable structures for future generations.