What is vibro-compaction?

3 February 2019Table of Contents

What is vibro-compaction?

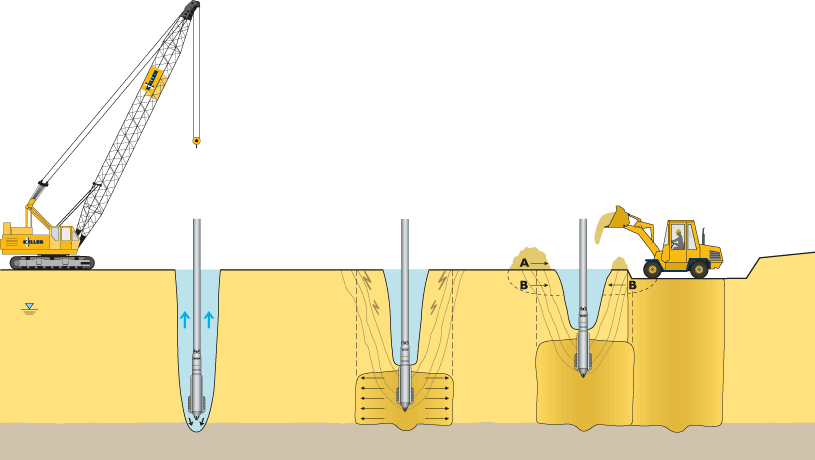

Vibro-compaction is a ground improvement method that uses a specialized vibrating probe for in-situ subsurface compaction of loose sandy or gravelly soils at depths beyond which surface compaction efforts are effective.

The vibrating probe densifies loose granular, cohesionless soils by using mechanical vibrations and, in some applications, water saturation to minimize the effective stresses between the soil grains which then allows the oil grains to rearrange under the action of gravity into a denser state.

Vibro compaction to densify loose, silty sands for an interim spent fuel cask storage pad in Braceville, Illinois.

Generally, vibro-compaction can be used to achieve the following enhanced soil performance or

properties:

• Increased soil bearing capacity

• Reduced foundation settlements

• Increased resistance to liquefaction

• Compaction to stabilize pile foundations driven through loose granular materials

• Densification for abutments, piers and approach embankment foundations

• Increased shear strength

• Reduced permeability

• Filling of voids in treated areas

Two rigs completing vibro compaction for liquefaction mitigation and settlement at a casino.

The vibrator is hung from a crane cable or, in some instances; it is mounted to leads in a similar fashion as foundation drilling equipment. The vibrator penetrates under its self weight (or crowd of the machine if mounted in leads) and, at times, with assistance from the action of water jets. The goal is that the vibration and water imparted to the soils ransforms the loose soils to a more dense state.

The Vibro Compaction Process

Advantages, Disadvantages and Limitations

1. Advantages

As an alternative to deep foundations, vibro-compaction is usually more economical and often results in significant time savings. Loads can be spread from the footing elevation, thus minimizing problems from lower, weak layers. Densifying the soils with vibro-compaction can considerably reduce the risk of seismically induced liquefaction. Vibro-compaction can also be cost-effective alternative to removal and replacement of poor load-bearing soils. The use of vibro-compaction allows the maximum improvement of granular soils to depths of up to 165 feet. The vibro-ompaction system is effective both above and below the natural water level.

2. Disadvantages and Limitations

Vibro-compaction is effective only in granular, cohesionless soils. The realignment of the sand grains and, therefore, proper densification generally cannot be achieved when the granular soil contains more than 12 to 15 percent silt or more than 2 percent clay. The maximum depth of treatment is typically limited to 165 feet, but there are very few construction projects that will require densification to a greater depth.

Like all ground improvement techniques, a thorough soils investigation program is required. Yet, a more detailed soils analysis may be required for vibro-compaction than for a deep foundation design because the vibro-compaction process utilizes the permeability and properties of the in-situ soil to the full depth of treatment to achieve the end result. A comprehensive understanding of the total soil profile is therefore necessary which typically requires continuous sampling or in-situ testing.

Equipment access over the site must also be considered. Since the operation requires use of a large crane, a relatively flat work bench with a width of at least 25 ft must be possible near all areas to be treated.

Wet vibro-compaction requires the use of water to jet the vibrator into the ground. The effluent from the jetting process requires at least temporary containment to allow any fine soil particles to settle out and be disposed. Further, this method of ground improvement may not be acceptable if the existing subsurface environment, either soil or water is contaminated. If contamination is present, use of water jetting may cause its dispersion and therefore other ground improvement methods should be considered.