Why does it cost between $25-$39 million to construct a kilometer of high speed rail in the European Union?

20 November 2018Why does it cost between $25-$39 million to construct a kilometer of high speed rail in the European Union?

This $25–39 million per km figure appears to be derived from a 2014 World Bank report that compared the construction cost of Chinese high-speed rail (HSR) projects to comparable European ones. In the same report, Chinese HSR costs ranged from $17–21 million per km, or roughly 30–50% less expensive.

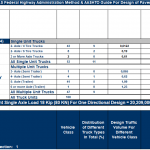

The best way to understand where these numbers are coming from is to dig into the major cost elements of your typical high-speed rail project. Here is a table from that report that looks at the cost breakdown of typical Chinese HSR projects at various speeds:

Source: World Bank — High-Speed Railways in China: A Look at Construction Costs (Page 4)

We will go through each of the categories above to explain how and where the cost differences may be coming from:

- Land acquisition and resettlement — HSR lines need to be pretty straight to accommodate high-velocity rolling stock and land usage rights along this path need to be acquired. Since property rights are weaker / less developed in China, it is fairly straightforward and thus relatively inexpensive to acquire these land usage rights. This also often involves displacement of existing populations and in China project planners factor in resettlement costs — mainly in the form of building new housing for displaced farming families.

- Civil works — As one can imagine, there is a ton of civil engineering and construction involved in high-speed rail projects. Unlike regular rail, high-speed rail lines need to be straight. To achieve this, you are often forced to build lots of raised viaducts or bore tunnels in hilly/mountainous areas. This was the biggest area of cost for Chinese HSR projects, a combination of (mostly) labor and raw materials (e.g. cement, steel, gravel, stones etc.).

- Track — Self-explanatory.

- Signaling and communications — Specialized systems to manage the entire system and make sure trains don’t crash into each other. Lots of signaling equipment, network equipment, fiber optic lines and software.

- Electrification — HSR trains are electric and draw power from the electrified track.

- Rolling stock — The high-speed trains themselves.

- Buildings including stations — Train stations and related intermodal links (e.g. local metro, bus station, taxi and airport).

- Other costs — Sometimes (but not always) capitalized interest is included in the total project cost.

The main reasons why European projects were more expensive most likely boiled down to a few key factors:

- Higher labor costs — Labor is the largest cost item in civil works and track-laying. European labor is several times more expensive than Chinese labor.

- Higher land acquisition costs — Stronger property rights in European Union countries means that project planners need to shell out more cash to acquire land along the line’s path. Paying more for the land is not necessarily a terrible outcome, as it represents an internal transfer of wealth from the public to landowners along the track’s path hoot necessarily good either). However, the bigger issue here are delays that it may cause in the construction phase if certain holdouts — leveraging their property rights — refuse to acquiesce (better eminent domain law/process can alleviate this). Longer construction periods translate into higher build and financing costs. To illustrate this point: The Chinese HSR projects usually took 3 to 4 years to complete once construction began while European projects took 2 to 3 years longer.

- Differences in economies of scale — The sheer scale of Chinese HSR allowed for significant standardization in process, technology, materiasl procurement and design. For example, raised viaducts were preferred in China to “minimize resettlement and the use of fertile land as well as to reduce environmental impacts” (page 5, World Bank Report). Following this, there were a massive number of viaducts that needed to fabricated and attached. So each section was built to standardized specifications (24 or 32 meters, weighing between 750 and 800 tons) and special machinery was invented to lay the viaduct quickly and efficiently.

There were differences in other categories as well, but much smaller in impact:

- Train stations — One thing you will notice about most new Chinese train stations (exception being “mega” stations in Tier I transportation hub cities like Beijing or Wuhan) is that they look quite similar in layout and design. This was done on purpose. Since they were building so many train stations at the same time, many of the designs were standardized from station to station which saved cost. Meanwhile you will notice that many of the European stations are quite unique in design. Basically, Europeans paid more for aesthetics, which while subjective is not necessarily a bad thing either.

- More expensive rolling stock — France (Alstom), Germany (Siemens) and China (CRRC) used mainly domestically manufactured trains for their networks. Chinese trains are less expensive, reflecting lower embedded labor costs as well as greater economies of scale in manufacturing.

- Raw materials — Another embedded cost item is materials cost (cement, steel and other raw materials), but since these are commodities, I do not think the cost difference would be that significant.

It is also possible that there were differences in terrain that increased the civil engineering requirements (e.g. bridges and tunnels), but you could really only assess this by looking at the detailed topography on an individual line basis.